The company was awarded a vendor contract for the floating pump station that will supply water to the state-of-the-art concentration plant with an annual output of 4.2 million of gold and copper ore to operate in the harsh continental climate (-45°C in winter to +45°C in summer).

During the bid, the professionals of Nord Minerals have demonstrated their high competence by providing a detailed design solution, which can fully satisfy the requirements of one of the most demanding customers in the industry.

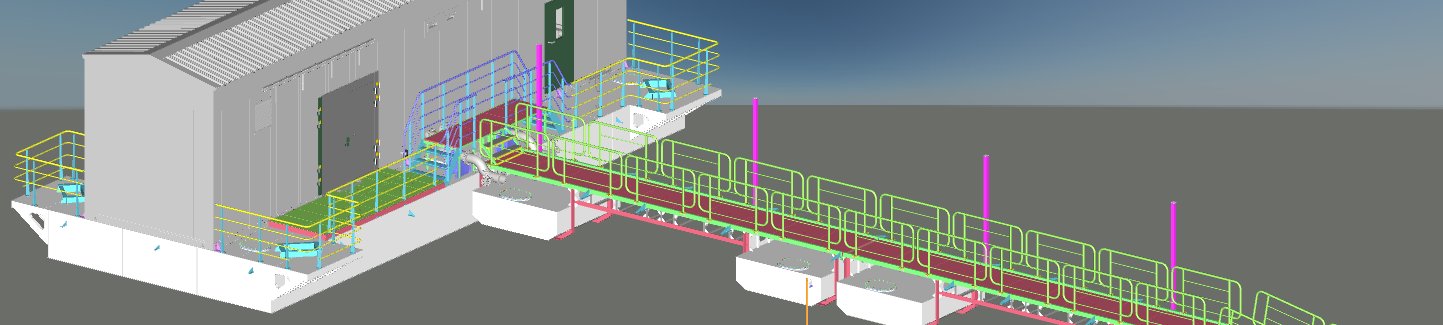

As in previous projects of Nord Minerals for the supply of floating pump stations, we have utilized the best practices in process automation, power supply, and process monitoring built around Schneider Electric equipment using pontoon tightness sensors and dual-compartment pontoons to increase the reliability, a discharge line priming vacuum system, a security alarm and access control system, a fire alarm system.

The design includes several technical upgrades:

Nord Minerals celebrates 5 years of cooperation with this client, where earlier interactions included the supply of ROITECH pump units and ELEMENT spare parts for Metso equipment.

The award of the floating pump station supply contract to Nord Minerals definitely proves the development of trusted partnership and acknowledgement of our company’s high competence and expertise in this area.