As part of the project for a lead-zinc ore processing plant, ROITECH pumps and a cone crusher were supplied. The new equipment showed less than 5% wear after six months of operation and has been running without failures for over a year. The developed 3D model of the workshop helped optimize equipment placement and ensure precise installation, improving process reliability. The supplied cone crusher enabled the enterprise to exceed its production plan within the first quarter.

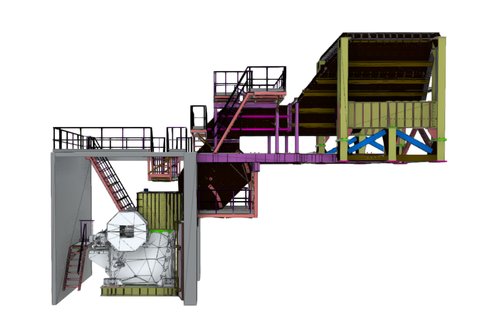

As part of the project to equip a new ore pass of the underground crushing and screening complex for one of the world’s largest chrome ore producers, a detailed 3D model of the installation was developed, forming the foundation of the engineering solutions. Created based on factory drawings, the model made it possible to optimize the design, manufacturing, and installation processes, ensuring high precision and accelerated project implementation.