After signing the contract in May 2024, the Nord Minerals team began working under tight deadlines and high risks to implement a project for one of the world's largest chrome ore mining, processing and beneficiation facilities located in Kazakhstan.

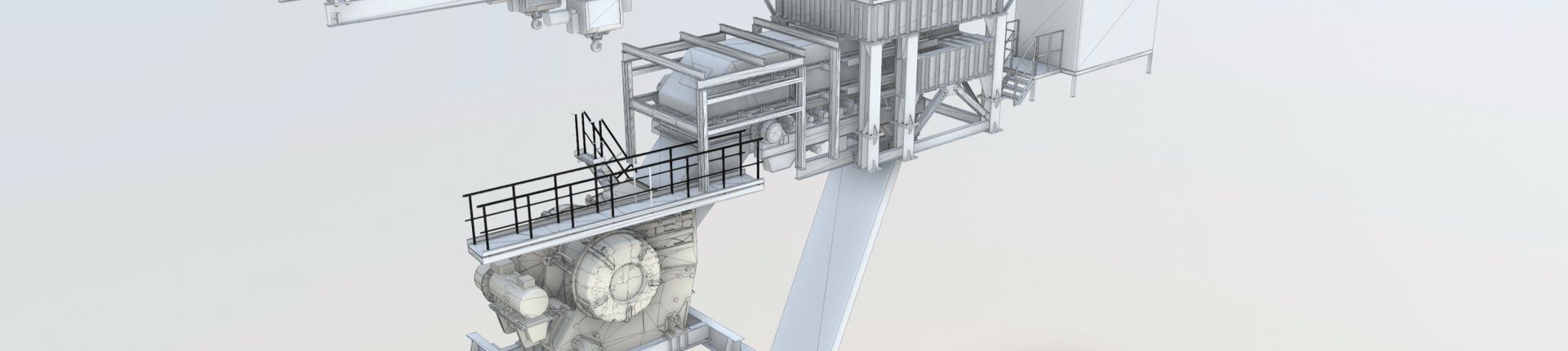

Project goal: to develop the solution for the construction of a 520 t/h crushing chamber in a mine and to supply the equipment.

During this project Nord Minerals had to solve several problems. First, the documentation had to be created quickly and efficiently in a few weeks, which included the main technical solutions, metal structures, electrical and automation systems of the complex, all of it supported by detailed calculations and 3D models. A key role in this process was played by a strong team from Nord Minerals' own engineering center, which immersed itself in the development and promptly took the lead in coordinating it with the customer. After developing a 3D model of the entire ore pass chamber, the customer was offered optimization solutions that significantly facilitated the project execution.

Two months after signing the contract with the customer, Nord Minerals not only completed a detailed project, but also managed to manufacture and ship within the stated time all metal structures of varying complexity, a hoist with a reduced construction height and a unique bimetallic lining with more than twice the Hardox performance. In addition to installation supervision and commissioning, the final delivery at the end of September will include the automation and electrification equipment for the entire complex.

This case is a testament to the ability of the cross-functional team at Nord Minerals to demonstrate the highest level of focus and responsiveness to deliver the project within a tight time frame.